MAGNETIC LEVERAGE

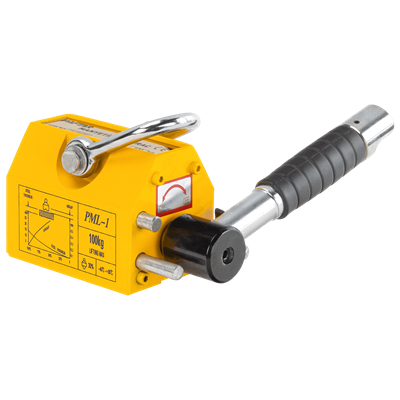

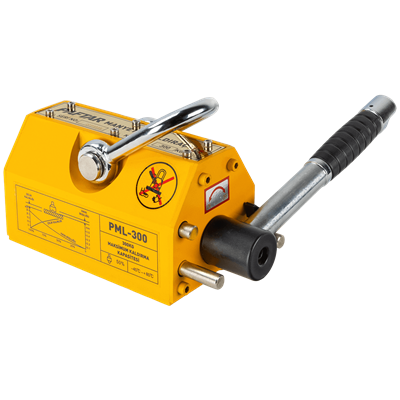

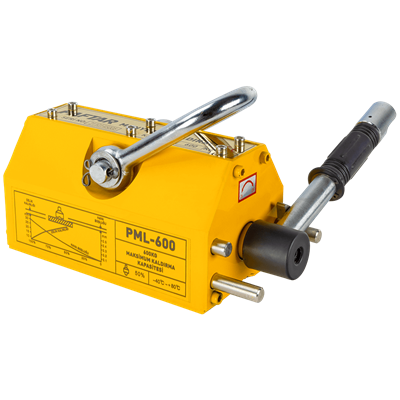

Magnetic Leverage is offered in different models and carrying capacities. PAFTAR's product range includes Magnetic Leverage models with various carrying capacities. These models, which can be selected according to the needs, stand out with their ability to lift different loads.

Magnetic Leverage is widely used in industries such as metal industry, construction, transportation and workshop. It is an effective solution wherever metal parts need to be lifted and moved.

Magnetic levers are lifting equipment that works based on the electromagnet principle. This system uses an electromagnet to generate a magnetic field in a controllable way. The basic working principle of magnetic levers is that the electromagnet attracts and lifts metal objects thanks to the strong magnetic field it produces when activated. When the magnetic field of the electromagnet is activated, the metal object is attracted and lifted by the magnetic force. In this way, magnetic levers are used to lift metal parts safely and efficiently.

There are some important considerations for the correct and safe use of magnetic levers. In addition, regular maintenance ensures the long-lasting and reliable operation of the levers. Here are some important points to consider in the use and maintenance of magnetic levers:

Usage:

- Weight Capacity: Care should be taken to ensure that the load to be lifted does not exceed the capacity of the magnetic lever.

- Surface Condition: The magnetic lever works most effectively when the material to be lifted has a flat and clean surface.

- Electricity Supply: The magnetic hoist must operate with the correct electrical supply. Electrical connections and cable integrity should be checked regularly.

- Safety Standards: Safety standards must be observed and necessary protective measures must be taken during use.

Maintenance:

- Cleaning: Magnetic surfaces must be cleaned regularly and free from foreign objects.

- Magnetic Field Control: The strength of the magnetic field should be checked periodically.

- Holding Power Test: The magnetic lever should be periodically subjected to a holding power test to evaluate its performance.

These measures ensure the safe and efficient use of magnetic levers, as well as regular maintenance and early detection of potential problems.

We are always with our customers for after-sales customer support with our wide and high quality service. We provide the fastest service for magnetic lever spare parts with our unlimited product spare parts stock.