CRANE

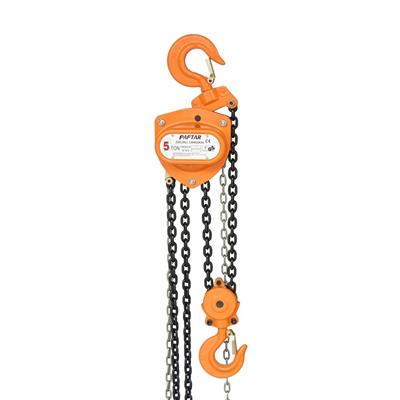

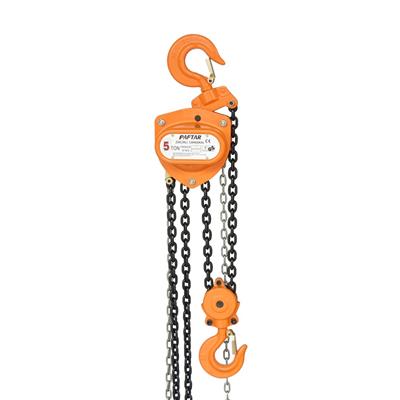

It is divided into 3 main categories as chain hoist, rope hoist and mini hoist. According to their working types, chain hoists are divided into manual chain hoist, 2-movement electric chain hoist, 4-movement electric chain hoist and double speed 4-movement electric chain hoist. The carrying capacity of chain hoist models varies between 500 kg, 1 ton, 2 ton, 3 ton and 5 ton. The lifting capacities of rope hoists are 1 ton, 2 ton, 3 ton and 5 ton, and the rope length is 9 metres and 12 metres. Electric mini cranes; While they have 2-moving and 4-moving working systems, they have lifting capacities from 250 kilograms to 1200 kilograms.

Crane task classification refers to the categorisation of cranes according to the intensity and frequency of use. It helps to determine the ideal type of crane required for a specific task.

The American Crane Manufacturers Association divides cranes into 6 according to their working classes.

Class A Infrequent Service

Class B Light Duty

Class C: Medium Service

Class D Heavy Duty

Class E Severe Service

The European Federation for Material Handling (FEM) classifies cranes according to factors such as number of load cycles, load spectrum and service life.

1Cm: Infrequent Use

1Bm: Light Duty

1Am: Light to Medium Service

2m: Medium to Heavy Service

3m: Heavy Duty

4m/5m: Heavy Duty

When choosing a crane, firstly; You should choose the crane model suitable for your sector and your business. Decide whether a manual or electric crane is suitable for your business as a working type. Let's not forget which of the chain or rope models is more suitable for your way of working. Another important feature you should pay attention to is the lifting capacity. You cannot work with cranes that are below your load. Finally, do not forget that the service unit should produce fast and permanent solutions when you encounter any technical problems. Does the customer representative communicate with you correctly except for technical specifications and service questions? Pay attention to this.

Cross load lifting causes the rope guide to break due to excessive load on the guide in rope hoists. In chain hoists, it causes the chain guide to break due to the contraction of the chain and its inability to rotate. Therefore, cross load should never be lifted.

No, it cannot be transported. If the crane is loaded with more than its capacity, the chain or rope may break and cause the crane to tip over. Let's not forget that carrying loads over capacity poses occupational health and safety risks.

The answer to the lifting height varies according to chain and rope hoist models. Lifting height can be increased in chain hoist models. We support our customer's additional chain request in their first purchase. However, the lifting height of rope hoists does not change. When the chain height is increased too much in chain hoists, there is a loss of lifting capacity, this is because both chain weight and vibration affect the lifting capacity as the height increases.

Yes, it can be transported. However, the crane capacity to be considered in liquid load transport is reduced to 50%. To give an example; You can carry 500 kg liquid load with a crane capable of carrying 1 ton solid load. This is because the liquid load is unstable and there is an extra load on the crane in case of shaking.

Paftar crane models; product quality, rich product range, professional working structure, reasonable price policy, spare parts from stock, professional service and customer satisfaction features.

Geniş ve kaliteli servis hizmetimizle satış sonrası müşteri desteği konusunda müşterilerimizin her zaman yanındayız. Sınırsız ürün yedek parça stoğumuzla vinç yedek parçaları konusunda en hızlı şekilde hizmet vermekteyiz.